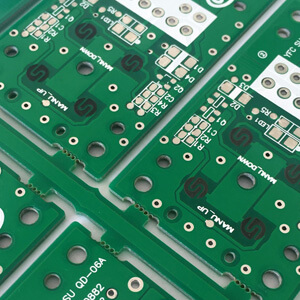

Solutions for Common Problems About PCB Dry Film Attachment

With the development of the electronics industry and the upgrading of products, in order to save board space, many PCBs have been designed with small lines. The previous wet film can no longer meet the current graphics transfer process, so it is generally small now. The lines are all produced with dry film.

Film attachment is important for PCB production, however, there would be some problems during manufacturing. To better solve such problems, we focus our attention on the reasons analysis, and offer some solutions for some common problems about pcb dry film attachment.

-

Air bubbles appear between the dry film and the surface of the copper foil

(1) Problem: Choosing a flat copper foil is the key to ensuring no bubbles.

Solution: Increase the pressure of the PCB film, and handle the board lightly.

(2) Problem: The surface of the hot pressing roll is uneven, there are pits and the film is dirty.

Solution: Regularly check and protect the flatness of the hot press roll surface.

(3) Problem: The PCB film temperature is too high, causing some contact materials to produce wrinkles due to temperature differences.

Solution: Reduce the temperature of the PCB film.

-

The dry film is not firmly attached to the copper foil

(1) Problem: The surface of copper foil is not properly cleaned, and the direct operation will leave oil stains or oxide layers.

Solution: Wear gloves to wash the plate.

(2) Problem: The quality of the dry film solvent is not up to standard or has expired.

Solution: The manufacturer should choose high-quality dry film and check the shelf life of the dry film regularly.

(3) Problem: fast transmission speed, low PCB film temperature.

Solution: Change the PCB filming speed and PCB filming temperature.

(4) Problem: The humidity in the processing environment is too high, which leads to a prolonged dry film bonding time.

Solution: Keep the relative humidity of the production environment at 50%.

-

Dry film wrinkles

(1) Problem: The dry film is too sticky, so carefully place the board during operation.

Solution: Once contact occurs, it should be dealt with in time.

(2) Problem: The board is too hot before the PCB film.

Solution: The preheating temperature of the board should not be too high.

-

Residual glue

(1) Problem: The quality of dry film is poor.

Solution: Replace the dry film.

(2) Problem: the exposure time is too long.

Solution: Have an understanding of the materials used and carry out a reasonable exposure time.

(3) Problem: the developer is ineffective.

Solution: Change the developer.