Assembly and Benefits of Quick Turn Circuits

The latest technology calls for speed. Music players, gaming consoles, mobile phones, drones, or any other device are obsolete because of speed as one of its primary factors. To stay in business upgraded and to the competition, speed and being ahead efficiently is crucial. Meeting the client’s needs quickly and effectively, thereby retaining affordability, is what keeps the customer’s demand in the business. One of these aspects can be met with the assembly of quick turn circuits. These give the customer and the manufacturer PCBs in short turnaround time.

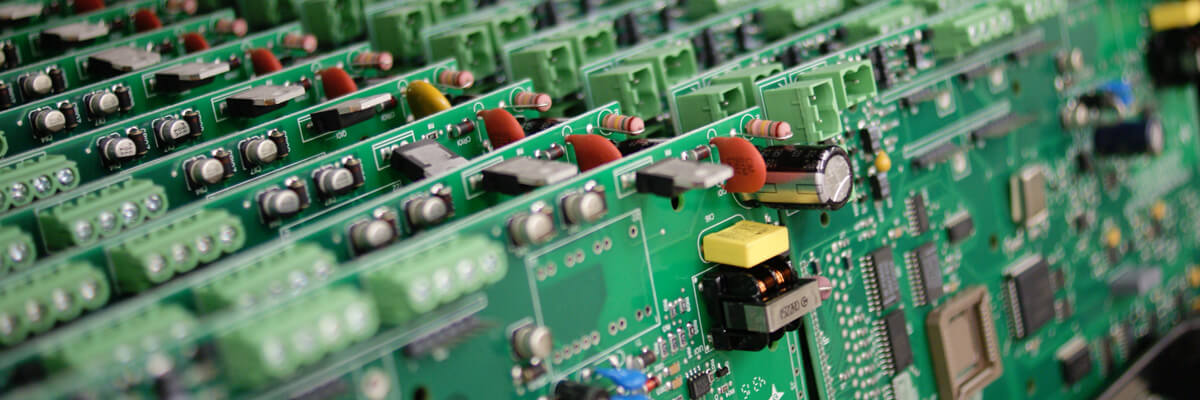

Big Transition- Hand Assembly to Machine Assembly

PCB or Printed circuit board came into being in the 1950s. They were assembled by hand initially, which were expensive and also time-consuming. There was a high chance of human error in this assembly.

Machine assembly made it possible to enhance the production time, accuracy, and precision. The components could be easily assembled, however small they may be. They could be altered easily and put to stringent testing. Quick turn PCB/circuits assembly can generate PCBs within days instead of weeks. This reduces the time of assembly and gives an edge over the current market competition. Quick turn is a factor dependent on the assembly of the circuit before the final fabrication.

Quick turn printed circuit assembly provides:

- Fast and reliable outcomes

- Minimize total costs

- Quick turnaround time

- Assembly from high-level expertise

- Thoroughly tested

- Flexible PCB

- Minimizes manufacturing time

- Quicker deliveries

What is the Assembly of Quick Turn Circuits?

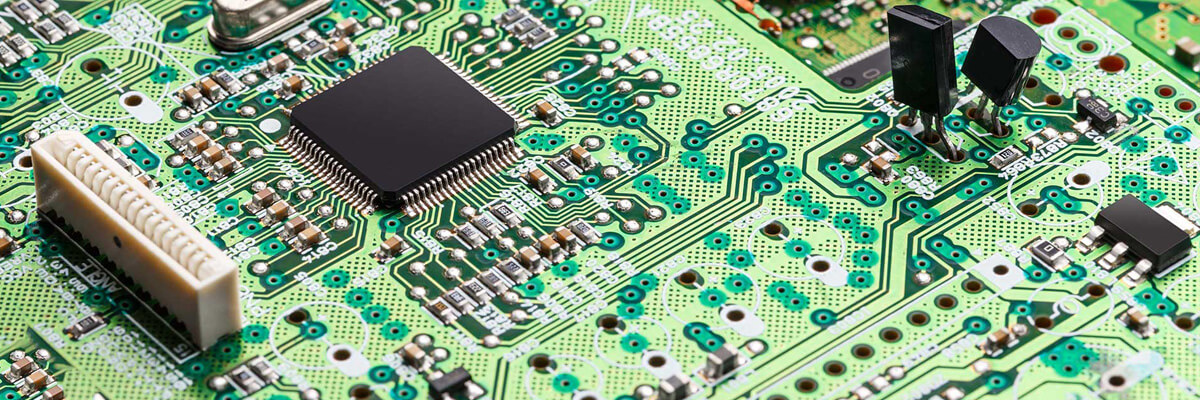

A quick turn circuit assembly is a procedure to link different electronic components onto a soldered board. The connections of these electronic components are established with the help of wires of PCBs-printed circuit boards. The wires are conductive paths or traces that are etched in the copper sheets that are laminated within a PCB. The lamination of the PCB is done with a non-conductive material or substrate that forms the circuit assembly.

This assembly results in a quick turn PCB that makes the manufacturing of the finally fabricated product with quick turnaround time. This ensures customers getting the delivered product timely and in a cost-efficient manner.

The Need for Quick Turn Printed Circuit Assembly

Quick turn circuit assembly enables customers to get their PCBs delivered on time. With a quick turnaround time, they are assembled to eliminate errors, customize to customer’s needs, with thorough evaluation and analysis.

https://www.europepcb.com/how-much-to-charge-for-pcb-assembly/

https://www.europepcb.com/pcb-assembly-prototype-manufacturing-sevice-2023/

https://www.europepcb.com/pcb-assembly-manufacturers-in-china/

https://www.europepcb.com/prototype-pcb-service-2023-5-functional-prototypes-you-can-get-from-pcb-manufacturers/

https://www.europepcb.com/products/express-pcb-product-cat/

https://www.europepcb.com/products/multilayer-pcb-product-cat/

https://www.europepcb.com/what-is-the-pcb-assembly-process/

https://www.europepcb.com/how-to-order-pcb-assembly/

https://www.europepcb.com/pcb-design-faq/

This assembly process enabled creating prototypes that are identical to the final PCB design tested for right operation. This eliminates errors in the final PCB fabrication. The prototype majors on the models of quick turn circuit assembly of PCB before final printing. This is why quick turn circuits assembly needs a confirmation of matching specs as requested by the clients before the finalization.

Some benefits of quick turn circuit prototype are:

- Reduces manufacturing costs.

- Eliminates mistakes and errors which do not ruin the original or final PCB fabrication.

- Saves time for the clients by meeting deadlines. Early checking of the quick turn circuit assembly enables features verification and operation of the PCB appropriately and quickly. It aids in saving time for the client and the manufacturer too.

- Adjustments to the circuit assembly can be made early, if any. Time efficiency also minimizes the costs involved in the assembly process. This is because once the final manufacturing process starts, it’s a clean and smooth process as no changes are required at later stages.

- Profits are optimized with a quick turn circuit assembly prototype. This is because you can take the feedback from the customer at the assembly phase itself without impacting final fabrication.

- Quick turn circuit assembly turnaround time is as low as 24 hours. It is very efficient in delivering an excellent final PCB for your customers.

Quick turn circuit fabrication is convenient and fast. It takes a day to meet the deadline. Some of the customers even save manufacturing costs and stress in the process.

Quick Turn Printed Circuit Assembly Types

Quick turn assembly takes from 24 hrs-5days. The turnaround is quick and incredible. However, a normal standard assembly takes about 5 to 10 days. An assembly process makes use of different types of solder. The manufacturer makes use of water clean, lead-free, and leaded fluxes. But the most preferred is the non-leaded soldering type. Post the process, the inspection of the PCB can be done extensively to make sure no rework is necessary. This is done with the help of a prototype. This will save money, massive loss of components, and time.

Two primary types of PCB mounting technologies are:

Smt or surface mount technology- Very small and sensitive electronic components such as diodes or resistors are automatically placed on the board. SMC assembly is applied to ICs-integrated circuits and smaller components.

Thru-hole-This technology works on wired and leads components that are board mounted by plugging them via the board holes. The additional part is soldered on the board’s contrary side. This assembly employs capacitors and coils along with other large components.

Three primary steps in quick turn circuit assembly:

- Applying solder paste to the circuit board or stenciling.

- Picking and placing the components.

- Solder reflow.

- Inspection.

- Quality control.

- Final inspection.

- Functionality test.

Which Quick Turn Circuits Manufacturer to Choose?

A right manufacturer is one who can offer the following:

Speed- Speedy delivery and meeting the deadlines are important. Time efficiency and quick turnaround time is a sign of good management. Manufacturers with no delays fall competitive in the market.

Efficiency- The product and the services of the manufacturer ought to be purposeful and efficient.

Quality- The final fabricated product ought to be of high quality and performance. The products should adhere to market standards and the client’s requirements.

Price- The affordability of the manufacturer is also a drawing point for customers. If you can get a reasonable price and value for your investment, the manufacturer gets an edge with customer and form a reliable customer database.

Conclusion

Assembly and fabrication of quick turn circuits are money and time-saving. It saves time for the customer as well as the manufacturer. The assembly is the deciding factor that leads to final PCB fabrication. A right circuit assembly eliminates errors, saves time and money without any rework required. With quick turnaround time, quick turn circuits can be very efficient and affordable.

If you want more information, please contact us.