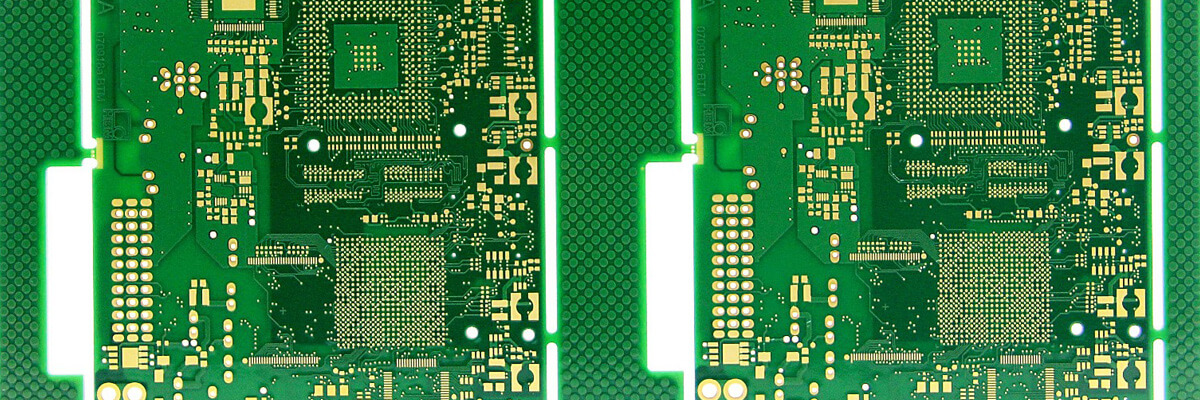

Quick Turn Around PCBs: Benefits and Manufacturer

Time is the most important factor now and then, today everyone is looking for things which are faster and advanced to save time. And PCB manufacturing not being any exception too needs a quick turn. It implies that the customer of the PCB manufacturer gets his work on time.

A lot of time is saved by the quick turn PCB to the customer and the manufacturer as well which could be invested in other work of profit.

Earlier it was a long process that took much time to manufacture a PCB but from the time being the arrival of quick turn around PCBs the period was lessened enabling quick delivery to the clients. It now takes just 1-3 days of working and may vary in terms of the sophistication of the requirements.

It costs from $10 and $50 being sure of the amount of produced units.

Studies of design may take little time especially when it comes to a "high-net-count" or "high -layer -count" PCB.

Importance of Communication in Quick Turnaround PCB

Communication is the key factor in manufacturing a PCB whether a small prototype or a large-scale order.

It is not a game for all manufacturers to produce complex designs in small amounts of time for advanced gadgets. However, if you want to then you can collect information in certain sectors before you begin to design and can easily lessen the amount of time needed.

1. Early Communication

Almost all the PCB designs get on hold all before entering the board line. The manufacturer's abilities, elements supply, or the key time are never looked upon by the designing team for the quick turnaround PCB order.

Better concepts or suggestions can help you with fresh board requirements like key time, handy components, or things like that while starting up with a layout just by calling or communicating directly with the designing team.

Ignoring this aspect of communicating may lead you to redesign or may broaden the assembly lead times. So to avoid this difficulty keep this factor in your mind.

2. Understand Assembler's Abilities

Another key factor in PCB manufacturing is turnover. The more the boards will be on the assembly line the more the company will earn the profit.

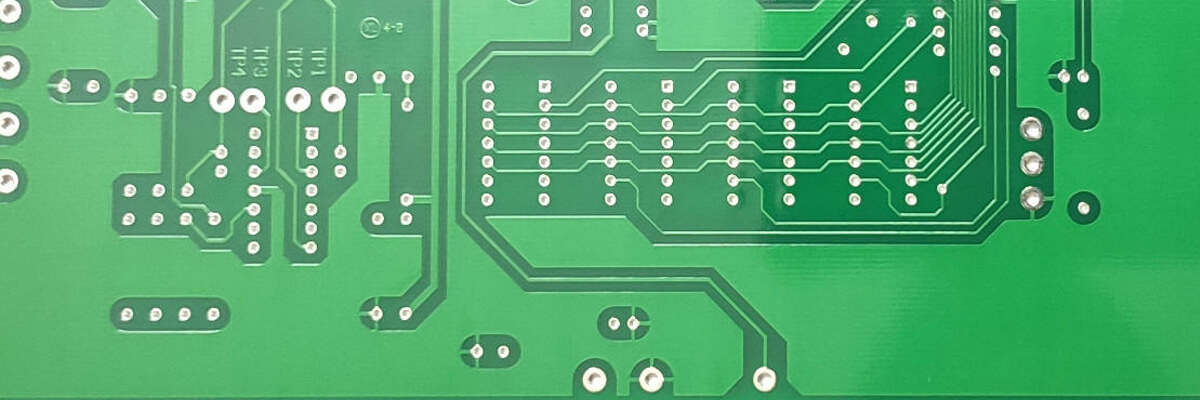

Easy layouts like spacing in between thermal vias, solder mask density, using thermal solace close to wide copper pour areas, and placing silkscreen are sometimes responsible for creating primary quality issues especially when your manufacturer cannot put up these choices of design. But there are many assemblers available who can easily put up these layouts or designs without ignoring the quality.

Your manufacturer can also instruct you that the vias in the thermal pad are placed properly or are too close to each other and can assist you to infer the right way of placing them to avoid the wicking of solder.

Choosing a design comes as an important thing to increase the yield but sometimes it happens that the design is not spotted and kept directly into production which increases the risk of low profit.

To avoid such a situation experienced manufacture is required who can place instructions to wreck a defected board with a simple inspection.

So to lower your turnaround timing understand the manufacturer's abilities.

3. Limited Work to Manufacturer

Provide your manufacturer a limited work that can be done on time with perfection. Putting on a bulk of work can put the manufacturer in a hurry to complete the work and so he may not be giving proper attention to quality.

Assure yourself that your manufacturer fits into your schedule and possesses bandwidth so that he can fit your order size as well.

Those who have specialized themselves in

quick turnaround PCB prototyping and assembly have also improved their strategies to put up low-volume, high-mix processing and may shortly bring your board to the manufacturing after they review the design.

Give him a fixed work and after its completion get him the other one.

4. Clear Testing Requirements

To contradict a manufactured board with the basic Gerber Data, a bare board experiment is used. To assure the testing requirements are obvious, you don't need to depend on just the Gerber board rather more than that. Here you must deliver a netlist to the manufacturer with the Gerber data.

The format of the IPC-D-356 netlist also can be taken on use to contradict a schematic netlist with the Gerber data of your board.

All this comparison and contradiction work should be done all before the assembly and manufacturing work gets started to assure that there are no contrasts.

Benefits of Quick Turnaround PCB

It saves not just the time but the processing cost as well. The fallacies and mistakes which have chances to occur on the actual circuit board can be prevented by the accessibility of fastening printed boards. This provides great help to the customer who has to modify the mistakes after the board has been manufactured, spending a lot of time and mind.

Now the manufacturer can do all the suitable variations at the early stage.

These provide sufficient friction to deviations and tendencies and also have a long duration.

However, you can make your quick turnaround PCB at home as well if you have certain things available at your home.

And if you know electronics then it is not a big task but it may take more time and money than that of professionals.

There are several ideas and tutorials out there on digital platforms like Google, Youtube, Browser, etc. So you can get help there and learn to make PCB on your own.

But it is better suggested that if you don't want to get into the electronic profession then don't waste time and rather purchase it from the market as it does not cost much as told above.

So these were some of the benefits of the quick turnaround PCB and how you can help yourself in finding a good manufacturer of these quick turn around PCBs. So, hope you find it relevant and interesting to your search.

If you want more information, please contact us.