Using Heavy Copper Board for PCB’s Maximum Reliability

Heavy Copper Board is the modern design for Printed Circuit Boards. PCBs are an amazing piece of technology. You will see them in all modern electronics. Without them, we highly doubt that these electronics could function.

Since they are an integral part of the electronics, they need to be reliable and efficient. You will be surprised to know that several designers and assemblers are unfamiliar with the copper usage in the PCB. They are not familiar with what is readily available in heavy copper PCBs.

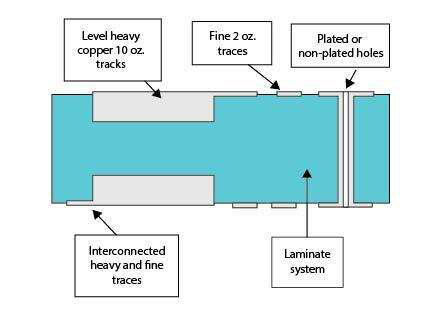

The good news about Copper boards is that you can have fine features. Even if the PCB contains 10 ounces of copper, it still can offer fine features.

Heavy Copper Circuit: A brief Overview

Manufacturers have come up with a series of heavy copper PCBs. You can gain access to single-sided PCB as well as to double-sided PCB. The thickness of copper varies from board to board. There are boards with just 3 ounces of copper. Then, we have boards that incorporate 20 ounces of copper.

Heavy Copper Printed Circuit Boards are expensive. However, with slight variation, you can enjoy cost-effective copper PCBs. For instance, a PCB with 8 ounces copper foil and FR4 substrate material would be extremely cheap. Either you can go with double or single-sided PCB. With the above feature, it would be the cheapest among Heavy Copper Boards.

For a multiple-layer copper, manufacturers can enjoy various layers. Most of these PCBs have four to eight layers. Each layer can contain around fifteen ounces of copper. To connect the layers, you need vias. These vias also contain heavy copper.

For assembling, it is imperative to use large thermal reliefs. This holds for both multi-layered PCBs as well as double-sided PCBs. This would ensure the effectiveness and reliability of the board.

Another interesting and advance copper Printed board is the multiplayer PCB that has 2 to 5 copper levels. To ensure its robustness, all these layers interconnection. In addition, the PCB’s layers are intertwined on one particular layer.

To ensure that a high current can pass, you need to have extra vias. The vias are located in the large pads. They also keep the pads attached. Thus, you get a strong pad to keep the cable intact.

The technological advancement comes with another robust and efficient PCB. You can now have a heavy copper incorporate 20 mils off the surface PCB. Thanks to advance equipment, the price is also within reach. The new technology reduces the price.

Even if you incorporate copper above and below the surface, the equipment will not make a drastic impact on the cost.

Assembling PCB Circuits

We understand that assembling of a heavy copper circuit is a daunting task. However, it is not impossible. With the right equipment and learned staff, the manufacturer can generate high-quality copper PCBs. You need to pay close attention to the thermal transfer. Ensure that you use the correct and efficient technique to transfer heat from the soldering iron to pads.

Effective transformation of the heat would enhance the PCB’s efficiency. Sometimes, you would have to hand solder a heavy copper PCB. This will help you do the soldering properly. Hand solder the PCB to the hot plate would yield better results.

To ensure that the pads remain intact, despite the retained heat, the manufacturer needs to work hard. They should use a laminate that is has a high-temperature and it is lead-free.

Problem with Heavy Copper PCBs

Yes, Heavy Copper PCBs are effective and efficient. However, they do have their demerits. It is possible to eliminate these issues with careful designing and manufacturing processes. Some of the most common issues are due to lack of full flow through the vias and the colder solder joints. When the other side of the via does not get full flow, it is bound to have an adverse effect on the performance of the PCB.

It is important to test heavy copper boards before you can solder them. The testing would help you understand the state of the PCB. Also, do remember that copper PCBs are heavier in comparison to the normal PCBs. Thus, copper boards do offer several advantages. The standard PCB, on the other hand, does not offer the same number of advantages.

Copper PCBs are perfect for day to day electronics that have a high-temperature requirement.

Why Use Heavy Copper in Printed Circuit Board Design?

Modern PCBs are no longer limited to several devices. On the contrary, you tend to see them in high current power devices. Devices that have electrically conductive networks. They transfer high current density all the time. To cater to this, manufacturers around the globe use copper boards. Having the right amount of copper would enhance the PCBs appeal. Yes, you need to focus on several layers of the PCBs as well. Some of these layers include the silkscreen, solder mask, traces, and substrate. Nonetheless, pay close heed to the copper element.

Since PCBs are a critical part of modern electronics, thus they need to be strong. Incorporation of Copper into PCBs offer numerous benefits. Below, we did tackle the question “Why use Heavy Copper in PCBs?”

Excellent Conductor

Copper is famous for its conductivity factor. It is an excellent thermal conductor s well an electric conductor. The incorporation of copper improves the heat transfer throughout the board. When the heat is smoothly transferred, PCB can efficiently perform.

After all, the lack of proper thermal management leads to poor PCB quality. The poor PCB would eventually lead to the failure of the electronics and causing a bad image of your company. Copper ensures complete electric conductivity. It means it can transmit signals without the loss of electricity.

Small Amount of Copper

Unlike other materials, the manufacturers do not need to use a large amount of copper. On the contrary, a small amount can do wonders. However, the more copper you incorporate, the higher efficiency the board will deliver. So, the amount of copper you use greatly depends on the conditions where the PCB will perform.

Unparalleled Thermal Resistance

Copper is among the leading materials that offer outstanding thermal resistance. So, when you use copper in PCB, you are bound to offer the reliability of the board. This then results in the reliability of the electronics. The product would be able to withstand extreme conditions. It also increases the mechanical resistance of the plated through holes along with the contact points.

Install Classic Heat Sinks

Another reason for using copper is that it allows direct installation of class heat skins on the surface. You can have either one side completely covered with copper or one side having heat generating power components. The copper-covered side would act as the heat sinks.

In both the above scenarios, there is a decrease in the assembling process. Thus, a decrease in the cost of the PCB.

Takeaway

With the above-mentioned reasons, there is no doubt that Heavy Copper Board is the best choice for modern electronics. Invest in copper boards instead of standard PCBs to yield better results. Hua Feng Circuit is the leading heavy copper board manufacturers. They offer high quality, robust and reliable Copper boards around the globe. Contact them now for all your PCB related queries.