7 Contemporary Pcb Manufacturing Skills You Can Learn From Double Sided Pcb Manufacturing Companies

Table of contents

1-Introduction to Customized Pcb Manufacturing

2-Printed Circuit Board fabrication with lots of improvements

3-Background of Customized Pcb Manufacturing- An Industry Overview

4-Customized Pcb Manufacturing Major contribution

5-What are the new features of double-sided PCB manufacturing?

6-Characteristics of modern Customized Pcb Manufacturing

7-Upcoming Customized Pcb Manufacturing boards

8-Customized Pcb Manufacturing Modern PCB Development Techniques

9-Double-sided Pcb Manufacturing Processes of PCB

10-Conclusion

Introduction to Customized Pcb Manufacturing

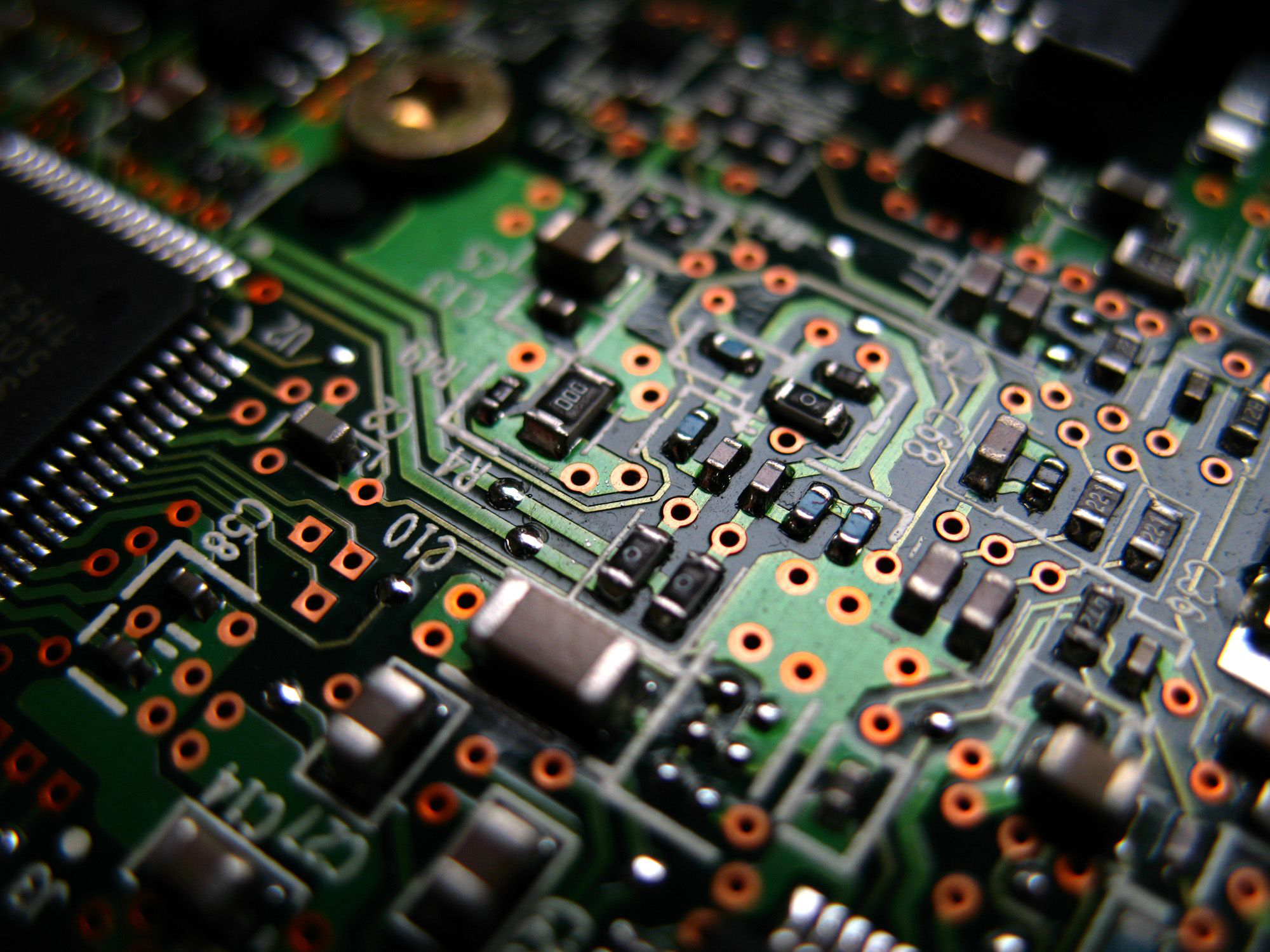

At present, almost all electronic devices companies around us hire Customized Pcb Manufacturing services. Similarly, the “printed circuit board” is an indispensable part to collect components inside the electronic equipment. Furthermore, we can say that these components have also had a significant impact on the performance of today's electronic devices.

Summarizing, a printed circuit board is a green plate or sheet component. In addition, some of you may have touched it during school technical learning hours. However, there are very few opportunities to learn about the function and characteristics of this printed board outside of schools and workplaces. Summing up, so many people do not know what is the purpose behind Double-sided Pcb Manufacturing in electronic devices?

For beginners also this Customized Pcb Manufacturing article is a very useful source which includes all the aspects,

- features

- characters

- And steps for PCB design and fabrication.

It also includes assembly, testing, and quality required for PCB. Moreover, this book has a basic introduction to the production of PCB. Instead of messing up with theories of the different fields; it contains principal and key points for the Double-sided Pcb Manufacturing design.

PCB

- PCB stands for Printed Circuit Board is also known as Printed Wiring Board (PWB).

- It is a thin electronic circuit board.

- Similarly, it has a lamination of copper on it.

Why it is called the PRINTED board?

The conductive areas are produced by means of screen printing which is used to print the drawing of the components. Therefore, Customized Pcb Manufacturing companies call it the “PRINTED” circuit board.

Printed Circuit Board fabrication with lots of improvements

Pcb provides a lot of alternate advantages too that other devices cannot deliver.

- PCB is small in size and less weight.

- Moreover, it gives a good yield at a low cost

- Double-sided Pcb Manufacturing and PCB fabrication can be done by machines

- The electronic equipment and systems used on the board are at a specific place which helps to recognize them and thus repair is easy

- Subsequently, the possibility of errors is less. In response, it reduces the time of verification the board

- Wiring on the boards are done by professional designers that is why chances of short circuits are rare

- Moreover, it has labeled traces and components on the board

- The parts on the printed circuit boards are immovable so it does not shake

History of Customized Pcb Manufacturing

Invention

Pcb manufacturing companies have been using printed circuit boards almost 50 years ago. Pcb Manufacturers started using it in nearly the 1950s.

Frank Sprague; he gave the idea of electric motors.

Thomas Edison was his advisor. Furthermore, he advised that the use of silver reduction can be applied. And many other efforts made for the production of PCB.

First contribution

Customized Pcb Manufacturing has contributed a lot in the past to develop a fully working for the printed circuit board. Moreover, some of the major names in history are here who have worked hard in PCB manufacturing.

Mr. Charles Ducas; on 2nd March 1925, he filled the patent application. He gave shape to the electrical metals to simplify the process. Similarly, he designed the conductors and used paste to form insulators. The stencils are then removed and the desired shape and thickness id formed. And electrical appliances are made.

Mr. Francis T. Harman; after 17 days a patent was filed for the duration of making PCBs.

Mr. Cesar Pasolini; on April 1928, France, he filled a patent for inventing electrical connections

Samuel Charles Ryder; in September 1928, Australia he filled the patent of manufacturing inductance coils.

Mr. Herbert C. Arlt; in July 1935, America filled the patent to avoid the use of wires.

Customized Pcb Manufacturing Major contribution

Dr. Paul Eisler; he proposed the base of the board and offered a copper-clad insulation material. Simultaneously, he also proposed Eyelets, the connection between both sides of the board. This contribution also defined the space and the weight of the board which is important in military products. Furthermore, he is also famous as the Father of the Printed Circuit Board.

- Why the printed circuit board is widely used?

- PCB printed circuit board is the most used connection device we are using today in the electronic gadgets.

- PCB is now an important component in this modern era as everyone is going toward globalization and using smart electronic equipment.

- Moreover, Customized Pcb Manufacturing companies are developing better designs.

- Also from the last few years everyone likes to use advanced and miniature products which are more handy and portable.

- Furthermore, it provides connection and support to the electric components

Q. What are the new features of double-sided PCB manufacturing?

Customized Pcb Manufacturing companies develop PCB design with

- Increase packaging density like high density interconnect structures

- Fine conductor tracks are used

- Thinner lamination

- Increased number of layers

Characteristics of modern Customized Pcb Manufacturing

Previously Customized Pcb Manufacturing companies design PCB with inserting holes on the board with the help of drill heads. But now ecofriendly inventions are coming on the horizon that is mounting the holes on the board. Mounting on the boards also increases the consumption rate of PCB boards. This technique carries out blind VIAs.

Q. What is mounting?

Insertion of components on the surface of theboard such as Connectors and capacitors is known as mounting. It has become a trend of inserting VIAs through holes to make it invisible. Simultaneously, the mounting position should be accurate.

Steps

Here are the basic steps Customized Pcb Manufacturing companies take for mounting components to the board.

- The first step is spacing on the board to mount a components

- A printed circuit board manufacturer should handle the whole process very carefully. Moreover, it will save the board from damage.

Upcoming Customized Pcb Manufacturing boards

For Introducing accurate, secure and boards with high functionality, Double-sided Pcb Manufacturing boards are now highly responsive and provide better resistance capacity. In addition, they will also have less budget requirements for fabrication. Moreover, it meets the market demand with appropriate quality.

Customized Pcb Manufacturing Fundamental Steps

Quality

One of the most important steps while verifying Customized Pcb Manufacturing is its quality. Moreover, a designer has to assure the quality of the circuit board. Such as

- The PCB design file must be valid, this is the responsibility of the designer

- DFM check means design manufacturing for a good quality

- The best quality check is during the process or while fabricating the circuit board.

“It is clear that drilling holes on the board lead towards most of the defects and bad quality of the board. For improving the quality of PCB, making holes smaller is not enough”

Electronic equipment for Customized Pcb Manufacturing

Electric components combine and flow of electrons through the connections make electronic equipment. Customized Pcb Manufacturing companies use Electronic equipment to send signals or electrons. Furthermore, wiring between the components has a long history. Manufacturing by hand was very popular. Pcb making on machines came later, but it was very effective.

“Customized Pcb Manufacturing companies use electronic components in every field of life”

- mobile phones

- V’s and some other appliances

- In hospitals such as monitors and scanning devices

- In aircraft, telecommunications industries, etc.

That is why there is a need for more dense, solid and small electronic equipment. And many bulky devices are now replaced by mini, compact and modern electronics.

According to the leading Customized Pcb Manufacturing companies Printed circuit boards are the best replacement of any heavily built component.

Q. Who Gave the Idea of eyelets in the PCB manufacturing process?

Dr. Paul Eisler who was the father of Customized Pcb Manufacturing gave the idea of eyelets. He proposed that’s eyelets. Similarly, said the connection between the conductors on both sides maintains through eyelets. But later on, it is derived that holes are used for plating layers.

- Using catalyst activator, the electrolysis method is introduced in 1960.

- He introduced Photo circuits in 1964. So, it means that a PCB manufacturer should plate specific areas with copper

- In the 1960’s the use of PCB become more popular. Subsequently, the fabrication and verification of PCB were done at that time.

In 1970s PCB had set its place to market. All the major electronics like:

- mobile phones

- laptops

- wireless devices,

- space crafts

- diagnostic monitors,

- Scanners etc. has PCB in it

Every major as well as minor Customized Pcb Manufacturing companies in china electronic equipment use printed circuit boards for better connections.

Customized Pcb Manufacturing Modern PCB Development Techniques

Pcb manufacturers introduced new techniques for the fabrication of printed circuit board such as:

- Photo film lamination

- Dry and wet film resist

- Solder masking

- Legend printing

- CNC drilling

- Reduction of the size of the board

- Manufacturing multilayers

- Manufacturing of rigid and flexible circuit boards

- Use of buried/blind VIAs

- Wet process chemistry

Customized Pcb Manufacturing -Progressive component technology

The use of PCB is so vast and this technology is dispersing all over the industries. That is why progressive improvement in the circuit boards is necessary. For example, introducing mounting technology and laser drilling.

High-Density Interconnect Structures (HDIS) are developing in many companies. Because the dense structure of the circuit board gives high connectivity function and fine features. Subsequently, HDIs have a high speed of the network and less wiring shortage. Other than that, a PCB with more resistance is required for high operating voltages systems.

Double-sided Pcb Manufacturing Processes of PCB

What is the Additive process?

Additive printing is also known as 3D printing. This is reverse manufacturing of the subtractive process. For example, the designer starts with FR4 substrate and then copper traces are added. This process will help the designers. It is a custom process that is why it causes less waste and cost.

- The additive process is more likely in PCB fabrication.

- Use of flexible circuit boards is more in use

- The circuit boards without using lead are more ecofriendly

PCB is an important part of Customized Pcb Manufacturing electronic equipment.

Components

The components of the printed circuit board include

Base;

- The base of the board is rigid or flexible

- A thin board of insulating material

- It supports all the conductors

- It gives support to the conductors

- All the electric properties depend on the base that is why a PCB manufacturer must control it

Conductor;

- Customized Pcb Manufacturing companies use thin strips of copper plating

- The copper strips are in the perfect size

Battery;

- The battery gives voltage to the circuit

Resistors;

- It controls the current passes to the board

- There are colored resistors used on the board

Inductor;

- It stores the charge on the board

- Then changes the charge into current

“Customized Pcb Manufacturing companies complete the whole process of PCB fabrication after tiresome mechanical support”

Conclusion

A Customized Pcb Manufacturing goes through a lot of planning and know known as an icon in the electric industry. The use of Printed circuit boards is worldwide.

“From 2010 it is calculated as 7% increase in the consumption of circuit boards.”

Similarly, PCB has many features and there is no big deal that PCB is successfully expanding. Furthermore, these boards have better functions and a reliable device used for connection which is unbreakable.

The greatest advantage of Customized Pcb Manufacturing is that they do not require wiring of electronic circuits one by one. Moreover, they have a low possibility of incorrect wiring and are excellent in mass production in a short time.

The base component is an insulating base made of epoxy resin or phenolic resin, which mainly does not conduct electricity. Subsequently, Pcb board making experts say that it is just a box without a computer and software, but it does not have any function even if it collects many high-performance ICs and electronic components.