PCB Manufacturing: A Comprehensive Guide to PCB Prototyping

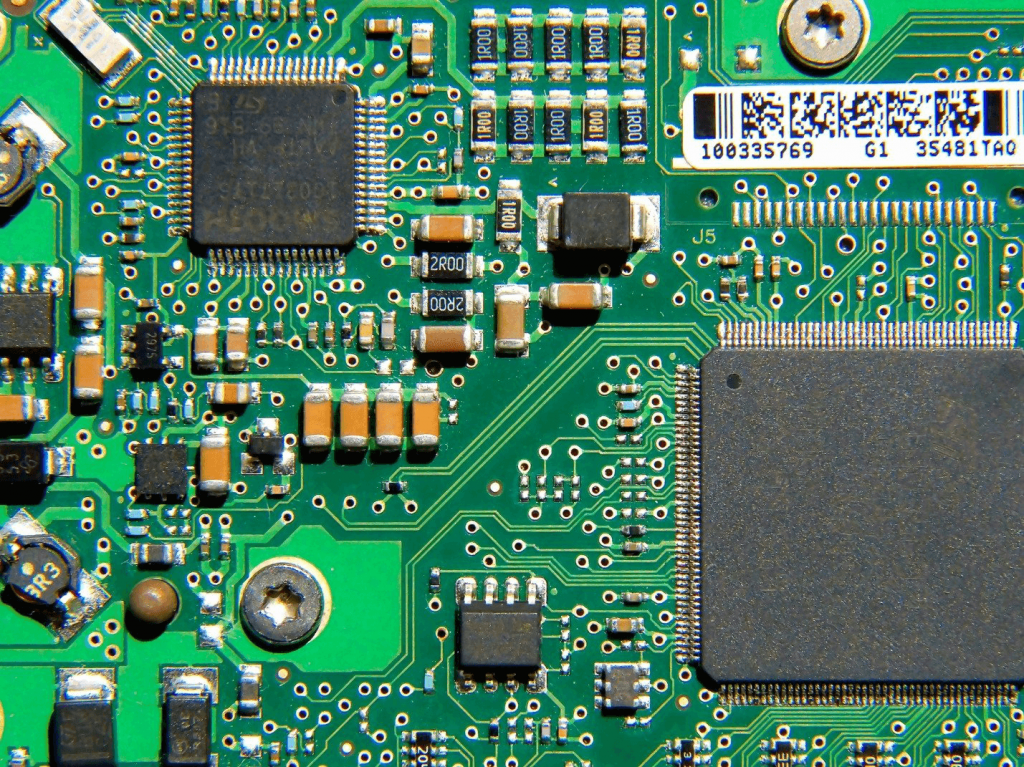

PCB manufacturing companies cannot deny the importance of PCB prototyping. It seems that Printed Circuit Board Prototyping is a vital part of the development cycle of the electronic product.

An experienced PCB prototyping can turn even the most complex designs of PCB into working prototypes. They have the skills, expertise, and equipment to do so. Nonetheless, it is important to have some basic knowledge about Printed Circuit Board Prototyping.

Here, we are going to present to you with a comprehensive guide on the basics of Printed Circuit Board Prototyping. So, without any further delay, let us get started.

Introduction to PCB Prototyping

In the case of a new component or a product, it is important for you to know that the desired product would perform as expected. Manufacturers today rely on a number of techniques including computer modeling.

However, it is not possible to get the true representation via computer modeling. Therefore, a good idea is to make the prototyping. With prototyping, you can have a first chance to see how the desired product would function.

It is like the design in flesh. With prototyping you can iron out any kinks well before you step down to the mass production phase. This would help eliminate any potential problems. Thus, it would save the additional cost that the manufacturer would have to pay by redoing the work.

Manufacturers, today always rely on PCB Prototyping as it helps generate effective and efficient results.

Importance of Printed Circuit Board Prototyping

Manufacturers around the globe acknowledge this fact that PCB prototyping is an extremely cost-effective way to test your design. It lets you find potential errors before the actual production phase.

With PCB prototyping, it is possible to optimize your design to ensure its efficiency and effectiveness. In addition, this time correction tends to save manufacturers a lot of time.

With passing time, consumer requirements are increasing. This is leading to more complex and complicated

Circuit Boards. With prototyping, PCB Manufacturing are able to test the basic functionality of their respective Printed Circuit Boards.

This helps them to add additional layers while removing any sort of error. Thus, they end up with a reliable, effective, and error-free product. With prototyping manufacturers are able to improve the performance of their final product.

In addition, working Printed Circuit Board prototype tends to offer additional business benefits. We agree, you use a breadboard to make minimum viable product. However, Printed Circuit Boards give a professional look. They offer a more permanent design.

After all, when you present a buyer with a working product, instead of series of schematics. He or she is bound to take your product seriously. You have a better chance of landing the buyer for investment or purchase.

PCB Prototyping Turnaround Time

In the real world, you do not have infinite time. Designers, developers, tester, everyone is under constant pressure of meeting deadlines. They need to complete several projects as soon as possible. Therefore, it is important to have speedy prototyping.

You simply cannot wait for weeks for just one turnaround time. They would simply render the product worthless, by the time it finishes. Make sure to have a speedy turnaround type for prototyping.

Of course, when you speed up the process, you are trading off some aspect. In most cases, it is either the quality of the cost. To have access to a prototype within a few days, you would either have a badly finished product or you would have to pay a premium price.

Since designers cannot afford to compromise on quality, the prices tend to raise. Likewise, engineers often compromise on the timeline to ensure the quality of the board. After all, their main objective is to design and develop high quality Printed Circuit Boards.

This type of PCB manufacturing mostly takes place in either Eastern Europe or Asia. In these places, labor is cheap. However, the turnaround time is not fast. It takes longer for the manufacture to deliver your product.

Nonetheless, there are certain Printed Circuit Board manufacturers in China that offer quick turnaround time with high-quality boards. One such example is CCTC-HFPCB. These are the best when it comes to Printed Boards of all types.

To make things easier, they offer different costs for different turnaround time. You can reach out to their customer services for further inquiry.

PCB Manufacturing: Prototyping Process

Below, we are going to talk about some of the most vital parts of the Printed Circuit Board prototyping process.

For starters, you need to use a reliable and specialist Printed Circuit Board partner. Firms like CCTC-HFPCB, always make the best out of their relationships. They will work closely with their clients. In addition, they are going to guide you at every step until the very end.

Their high level and outstanding customer service along with their years of industry experience makes them an ideal Printed Circuit Board partner.

Schematic

First thing first, you need to have a Schematic. In case you are wondering what a schematic is? Simply, read on.

It is the basic print of the Printed Circuit Board. This blueprint shows all the components as well as their linking with each other. It gives away the basic layout of the entire Printed Circuit Board.

There are different software available for the creation of a schematic. These basic circuit software would make your life easy. More advanced software provides the facility to turn your schematics automatically into Printed Circuit Board files.

This would make designer’s life extremely easy. So, make sure to choose a software that can convert the blueprint into a PCB file.

Design Optimization

Design optimization holds great importance. There are several ways in which you can optimize the design of your Printed Circuit Board. With design optimization, you can actually identify different parts of the Printed Circuit Board.

Not only this, but it also makes it easier for you to group these identified products together. For instance, on a circuit that has a power supply, it is a good idea to keep the audio output and the audio input together in a group. Doing this would reduce the trace distance between components.

In case, you fail to do so, the traces would be long and they would cause trouble. A good designer understands that long traces cause noise and unwanted interference. It is important to ensure that the electrical current’s path is linear.

The more linear it is, the better it is for the Printed Circuit Board. When each section has traces of the same length, they will get the same voltage. Thus, improving the overall functionality of the Printed Circuit Board.

Also, you need to focus on the interaction of Printed Circuit Board with the final product. If there is an LED near the power switch, think about how this would look in the final design.

Multilayer PCBs

We understand that fitting large circuits into a single-layer Printed Circuit Board is not a viable option. Therefore, we do recommend that you opt for Multilayer Printed Circuit Boards. Routing traces without interaction is a challenging thing with a single-layered Printed Board especially when you are dealing with large circuits.

Take Away

There is no denying the importance of Printed Circuit Boards as well as their prototyping. High quality Printed Circuit Boards would increase the overall efficiency, effectiveness and lifespan of your final product.

Therefore, it is imperative to choose the right PCB Manufacturing company. We, at CCTC-HFPCB, promise to deliver only the highest quality Printed Circuit Boards. Our designers and developers would help you at every step.

Regardless the complexity of your Printed Circuit Board, we are able to generate error-free and high-quality Printed Circuit Boards. Our years of experience allow us to make the right decisions at the right time. We are able to deliver mass volume Printed Circuit Boards within a short time.

You will never have to worry about the quality, as we would never compromise on it.