Ceramic printed circuit boards (PCB) or ceramic PCB are getting more popular amongst circuit boards for their great performance. When you are looking for the best type of ceramic PCBs, you need to be aware of some essential information. The Huafeng manufacturer will provide a detailed introduction below:

What is a ceramic PCB?

What are the basic types of ceramic PCBs?

Application of ceramic PCB?

Advantages of Ceramic PCB

Disadvantages of Ceramic PCB

Why Choose Hua Feng PCB Manufacturer?

Conclusion

What is a ceramic PCB?

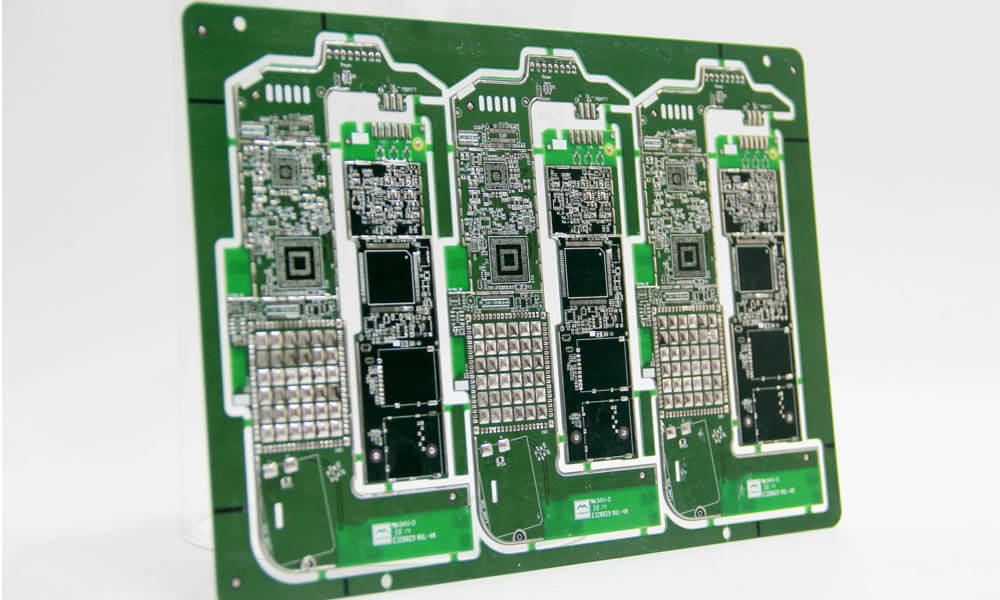

Ceramic PCBs are circuit boards with a ceramic base. In this case, conductive pathways are printed on Ceramic-based materials. It is better than metalcore or FR4 circuit boards for its higher conductivity and many other great features that make Ceramic-based circuits the best. Ceramic boards were made for fitting compact spaces while not having problems due to heat dissipation or the coefficient of thermal expansion. They are superior to traditional circuit boards in many ways which will be discussed below.

Materials

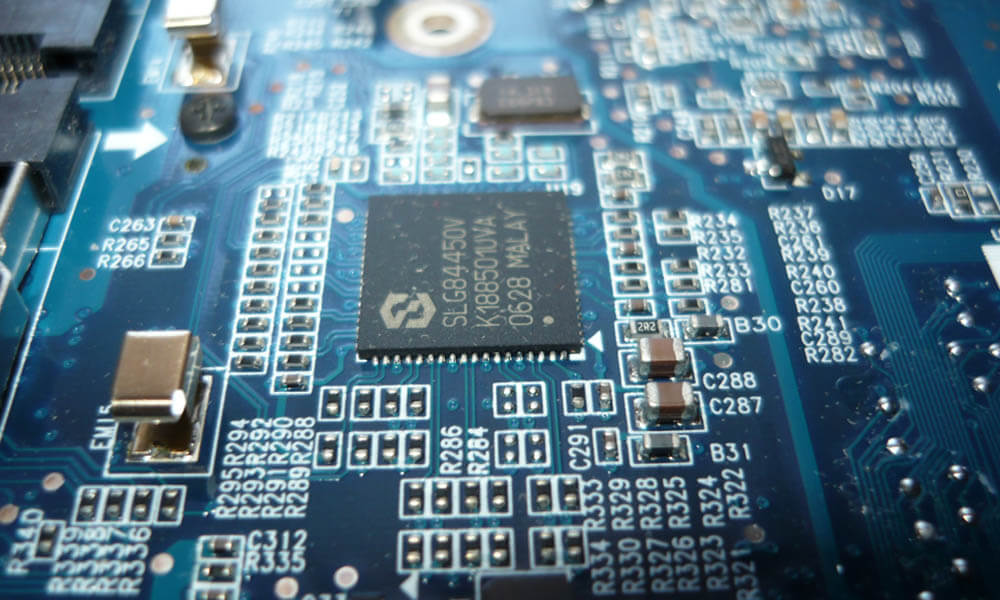

Ceramic boards are made of high-quality materials. These are not the ceramic that your floor has. Ceramic boards consist of metal cores. The metal cores are made of Aluminum Nitride, Beryllium oxide or Aluminum oxide. 96% to 98% of these materials are present in the circuit. Aluminum nitride and Beryllium oxide give the best performance but when you have a lower budget, the Aluminum oxide can be chosen. Aluminum nitride circuit boards’ conductivity ranges from 150-170W/mK while Aluminum oxide’s conductivity is 29W/mK which is much inferior to Alumina-based circuit boards. As a result, for more conductivity, you should choose Alumina-based printed circuit boards.

The conductor materials differ in different cases. For thick or thin-film technology, materials such as silver palladium (Ag-Pd) or gold-palladium (Au-Pd) are used. Direct Copper Bonded (DCB) conductors use only copper. The gold conductor is far better from silver for not having silver-corrosion problem but the conductivity can be increased by using silver traces covered with glass. While using delicate pieces of machinery, gold is a better choice.

What are the basic types of ceramic PCBs?

There are mainly three basic types of Ceramic-based printed circuit boards. These are differentiated according to the versatility of manufacturing methods. The three types are:

1. Thick Film Ceramic Board

Thick film ceramic boards have a conductor layer that exceeds 10 microns. The thickness is less than FR4 or DCB board. Using thick-film will allow us to utilize:

- Resistor

- Electric capacity

- Conductor

- Semi-conductor

- Interchangeable conductor

2. Thin Film Ceramic PCB?

Thick film ceramic boards have a conductor layer that is less than 10 micron. These boards are smaller in size and much more expensive. It is mostly suitable for microwave circuits.

3. DCB Ceramic PCB

Direct Copper Bonded (DCB) circuit boards where the aluminum nitride or aluminum-oxide is directly bonded with the copper foil under high temperature. Being very thin, it is good for:

- High-quality electrical isolation

- Fine solderability and high bonding strength

- High thermal conductivity

Like FR4 PCB, it can be etched into different layouts.

Read more: What is Thick Copper PCB?

Application of ceramic PCB?

For their high-quality thermal and mechanical advantages, Ceramic PCBs are used in various fields. The board’s unique feature and high thermal conductivity have enabled it to be used in devices big and small.

-

Memory modules

All RAM requires high-quality ceramic-based boards. Ceramic board is used in DDR SDRAM and other parts that are related to memory. As the memory module needs to be well-made and should have the ability to endure extreme usage, Ceramic-based boards are used.

-

Multilayer Interconnect Board

Ceramic allows more components than traditional PCBs on the same surface. Ceramic’s capacity for facing weight is very high. This is why ceramic-based PCBs are better than conventional boards when used as multilayer interconnected boards.

-

Receiving & Transmission Modules

Transmission and receiving modules were first created using Ceramic PCB by American firm Westinghouse. Since radars need to be highly accurate, the board used in them should have compatible CTE and high thermal conductivity. Ceramic boards are very useful for receiving and transmission modules.

-

Analog/Digital PCB

This may sound like using circuit boards to make circuit boards. LTCC or low-temperature ceramic circuits have been used by different computing firms that assisted them in making supreme-quality analog and digital boards with excellent circuit tracing. By creating a host of lightweight circuits, personal computers have become lightweight.

-

Solar panels

HTCCs (High-temperature ceramic circuits) and LTCCs (Low-temperature ceramic circuits) are used in solar panels and many photovoltaic panels. To ensure high-quality thermal conductivity and longevity, PV panels use multilayer ceramic boards.

-

Electric Power Transmitter

Wireless chargers are getting more popular. These wireless transmitters have been made possible by using Ceramic printed circuit boards. Their high-quality thermal properties make them perfect for electric power transmitter. By creating an electromagnetic field, Ceramic boards can transfer electrical energy. Sometimes, the receiver is also made from Ceramic-based circuit boards.

-

High Power LED

Ceramic circuit boards are mostly used in this field. Thick-film ceramic boards have superior thermal efficiency. Since LED lights produce a lot of heat (70%), it is essential for a system to have high-quality material that can withstand the heat. Ceramic boards do not have any adverse effects due to the immense heat and that’s why it is perfect for high power LED.

-

Semiconductor Cooler

Using the micro-fabrication method, semiconductor chips have superior tracing with high integration and tracing. A modern-day semiconductor chip needs Ceramic circuit boards to function well. This is mostly because it needs to be fitted into tight space and traditional PCBs fail to do that.

Advantages of Ceramic PCB

There are some great features of ceramic printed circuit boards that are not available in other PCBs. Such features have made it unique and usable in conditions that traditional PCBs can’t withstand. There can be a lot of advantages that can be mentioned but the following ones are the most well-known. Know that the following are not specified to a specific type of Ceramic board but apply to general ceramic-based circuit boards.

1. High-quality thermal conductivity

Thermal conductivity is a term that means the ability to transfer heat energy. The thermal conductivity of the Ceramic circuit board is higher than any other PCBs. This high thermal conductivity allows it to be used in high temperature as it can withstand it very well and don’t get damaged at all. For high durability of electrical devices and great performance, many use ceramic boards as it gives good temperature control. Traditional PCBs can get easily damaged by excessive heat and that’s why high-powered LED lights use Ceramic PCB. The thermal conductivity values are:

- 24W~28W/m-K for aluminum oxide

- 150W~240W/m-K for aluminum nitrite

- 220~250W/m-K for Beryllium oxide

2. Easy multi-layering

Ceramic can allow easy multi-layering for having high mechanical strength. It can easily support the weight of other components which lets anyone have multiple layers. More layer of such circuit boards means it the device can do more complex works. This results in increased performance for devices.

3. Superior insulation

Having good insulation leaves a board unaffected from any type of voltage issues. Typically printed circuit boards face a lot of problems for voltage-related issues. In the case of Ceramic printed circuit boards, such issues don’t occur since Ceramic has very high-quality insulation. Such insulation lets Ceramic-based PCBs insulate the electrical resistance effectively. It also gives extra safety with its ability to withstand the inconsistency of voltage. By using a ceramic-based PCB, an electrical device has better protection against voltage problems which results in safer and more durable products.

4. Low dielectric constant

Ceramic-based boards have low dielectric constant. What it does is allowing the board to work perfectly even in high temperature and high humidity environment. As a result, in extreme conditions, a Ceramic board is more likely to be able to work without any problems than traditional PCBs. It does not only adds to the safety of an electric device but also increases the quality.

5. Low thermal expansion

We know that metal expands when it gets the touch of heat. It causes a lot of issues in a Circuit board and sometimes they get heavily damaged. To keep the thermal expansion at a minimum level, you should use the Ceramic PCB. Ceramic has a very high heat capacity and will not expand in contact with heat. This is another criteria where Ceramic boards take the win.

6. High cosmic ray resistance

Ceramic boards are used in aerospace. Its high cosmic ray resistance makes it suitable for such a field. Space has a very high quantity of cosmic rays and radiation. Such radiation can damage anything including boards. General PCBs can get damaged over time with the contact of radiation. This is why ceramic PCBs are used in aerospace.

7. Compact

One thing that developers have always wanted is circuit boards to be smaller and fit compact spaces. Thanks to Ceramic boards that now complex works can be done in a small space. That is why we have smaller devices that can work great.

8. Durable

Ceramic boards are very durable as they can withstand extreme heat and pressure. They work well because of Ceramic’s high-quality weight and heat withstand capacity. They last longer than traditional circuit boards and this is why they’re a better choice.

Disadvantages of Ceramic PCB

There are only a few disadvantages that can be found in ceramic PCBs. If considering all the advantages and flaws, Ceramic PCB surely takes the win amongst all other boards. Some of the main disadvantages are stated below.

1. Cost

There is a reason why Ceramic-based circuit boards are mostly used in aerospace and complex machinery. They are more expensive compared to other printed circuit boards. For this reason, such PCBs are hardly found in household electrical devices. But one thing to consider in this case is the after cost. Other printed circuit boards might get damaged and for repairing or replacing, you might have to spend an extra amount. On the other hand, Ceramic boards are very durable and you won’t have to worry about repair costs.

2. Handling

Handling Ceramic-based boards can be very complex as the material is fragile and small. If any problems occur with the board, it will take some effort to fix it. As Ceramic PCBs are made for tight spaces, they are very small and this makes them even harder to handle.

3. Availability

Ceramic printed circuit boards are scarce. The scarcity of these boards makes them more expensive. Unlike other circuit boards, Ceramic-based boards have low availability. This makes them hard to find. You might have to spend some time until you find your preferred circuit board. There are some online selling services that provide high-quality Ceramic boards but there is no exception to the high price. The number of ceramic PCBs is also small, which increases their scarcity.

Why Choose Hua Feng PCB Manufacturer?

Choosing the right PCB manufacturer is imperative as the future of all your electrical products greatly depends on having the right PCBs. Therefore, we suggest that you select Hua Feng as your printed circuit board Manufacturer.

Being the leading cheap Chinese PCB manufacturer, we offer the best quality at the most competitive price. Our years of experience in the PCB manufacturing industry allow us to design and develop products that are robust and reliable.

We promise to deliver high-quality products that will meet your requirements to perfection. Hua Feng ensures that each PCB meets the highest industry standards. We thrive to deliver only the best quality products to our consumers, as we firmly believe in satisfying our consumers in every way possible.

We use modern, state of the art equipment to ensure high quality Printed Circuit Boards. Regardless, the type of PCB, Hua Feng, will develop high level, robust printed circuit boards. Here are the reasons for you to choose us as your Ceramic PCB manufacturer.

Conclusion

Ceramic PCBs are the answer to many great problems we had before with traditional circuit boards. With the utilization of Ceramic-based circuit boards, a company or brand can produce higher-quality devices that are able to withstand high temperatures. Using Ceramic is a milestone in the field of printed circuit boards and it is now used in great quantities. To be on the competition, a brand has to start utilizing these materials for providing better devices to clients. Ceramic boards are truly the future.